The Saga of the Generic Pleater Needles

- Lisa Hawkes

- Jun 11, 2016

- 4 min read

Updated: Sep 2, 2022

I was heading off on vacation for a few days and planned to take a baby angel sleeve bishop with me to smock on the beach. My nephew and niece are expecting their first little one and the shower is two weeks away. Now before you accuse me of procrastinating, I have been working along diligently. The bloomers to go under the bishop are all sewn (and turned our adorable, as bloomers usually do), the angel sleeve bishop had the arms attached, and my bags were packed. The last thing on my “to do” list before we headed out the next day, was to pleat the bishop.

At 4 p.m. on a Saturday I set up my pleater. To make sure the pleating went smoothly, I thought it might be best to break out a new set of pleater needles. The current ones had been in the pleater for quite some time, and pleating over the seams of a bishop can be difficult, so best to use some sharp, new needles. I wasn’t sure if the new needles were the same as the ones currently in the pleater, so I switched out all of them. I wasn’t leaving anything to chance! Off we started and all was going well – I was over the first 3 seams and coming down the home stretch to that fourth seam. But then it happened – going over that last seam, I heard the dreaded crunch, and a needle was broken. I carried on to the end hearing an unusual scratching noise. Out came the bishop from the pleater with the hopes that it was still salvageable. Perhaps I could block it on the smocking board and with a hand needle feed the thread through the remaining pleats. But upon on close examination, that scratching noise was caused by the two adjacent needles coming unthreaded and riding over the top of the fabric. I had never had that happen before. What had caused it? With three needles right next to each other not feeding the thread through the pleats properly, there was no way to save it. Time to start over!

This time I didn’t make it over the first seam. Now just to be clear, I was using a nice 100% cotton fabric that was going through the pleater like butter, until I got to the seam. I wasn’t being greedy and trying to get that pleater to go over French seams, no, I was taking the easy way out; these were just plain old seams, trimmed and zigzagged. Yes, there were two layers of fabric, but really the pleater should be able to handle that! I have made two other bishops this year using this method, and haven’t broken a single needle doing it. The needle that broke this time around was the first needle – the top holding row. There is no way to get the neck binding on nicely without that top holding row, so time to try again.

Third time up – I made it over the first seam with no dreaded crunch! But then all of a sudden there was that horrible scratching noise. I looked and there it was, two needles riding above the fabric and not feeding the thread through the pleats.

Now there are certain rules and laws when it comes to pleating, and if you don’t want to aggravate the pleating gods, then you had best mind them. I didn’t mix types of needles – they don’t like that. I wasn’t trying to go over French seams. I wasn’t going fast when I came to the seam, no, I was going slow, being gentle, and not allowing my pleats to accumulate on the needles. I was even slowly rocking the pleater as I eased over the seam. Now everyone knows if you do all those things, and you make it over the seam without hearing the dreaded crunch, then you are home free until the next seam. This is how things work in the land of pleaters, unless of course, you have used DREADED GENERIC PLEATING NEEDLES! Dreaded generic pleater needles do not follow the rules. Pleater needles break or pleat – the only two viable choices for pleater needles. But no, DREADED GENERIC PLEATER NEEDLES, bend! That’s right, I took those needles out, took a look at them, and saw that those needles had bent just like play dough and were riding above the fabric making that awful scratching noise!

At this point, I did what any sane person would do, went to go make dinner and pour myself a glass of wine. If we weren’t leaving the next day, I would have put pleating out of my mind and come back another day, but that wasn’t a possibility since I needed to take the dress with me.

So after dinner, back to the pleater I went, and put the old needles back in. Off we started and yes, there was that crunch again, but not until the last pleat and this time, in the bottom holding row. Breaking a needle is one of the viable options for pleater needles, and these were the old needles, so I couldn’t get too upset. For the sake of my sanity, and the sake of the pleater, I am making this work without the bottom holding row over the last part of the back of the bishop. When all was said and done, I realized that I broke 2 and bent 9 of the new needles! I have never seen needles bend like this! What will I do in the future – I am not sure? I have a Sally Stanley pleater and the needles are not made anymore. I certainly will not be buying anymore generic pleater needles! I might also have to start pleating my bishops in pieces! Have you had trouble with the generic needles?

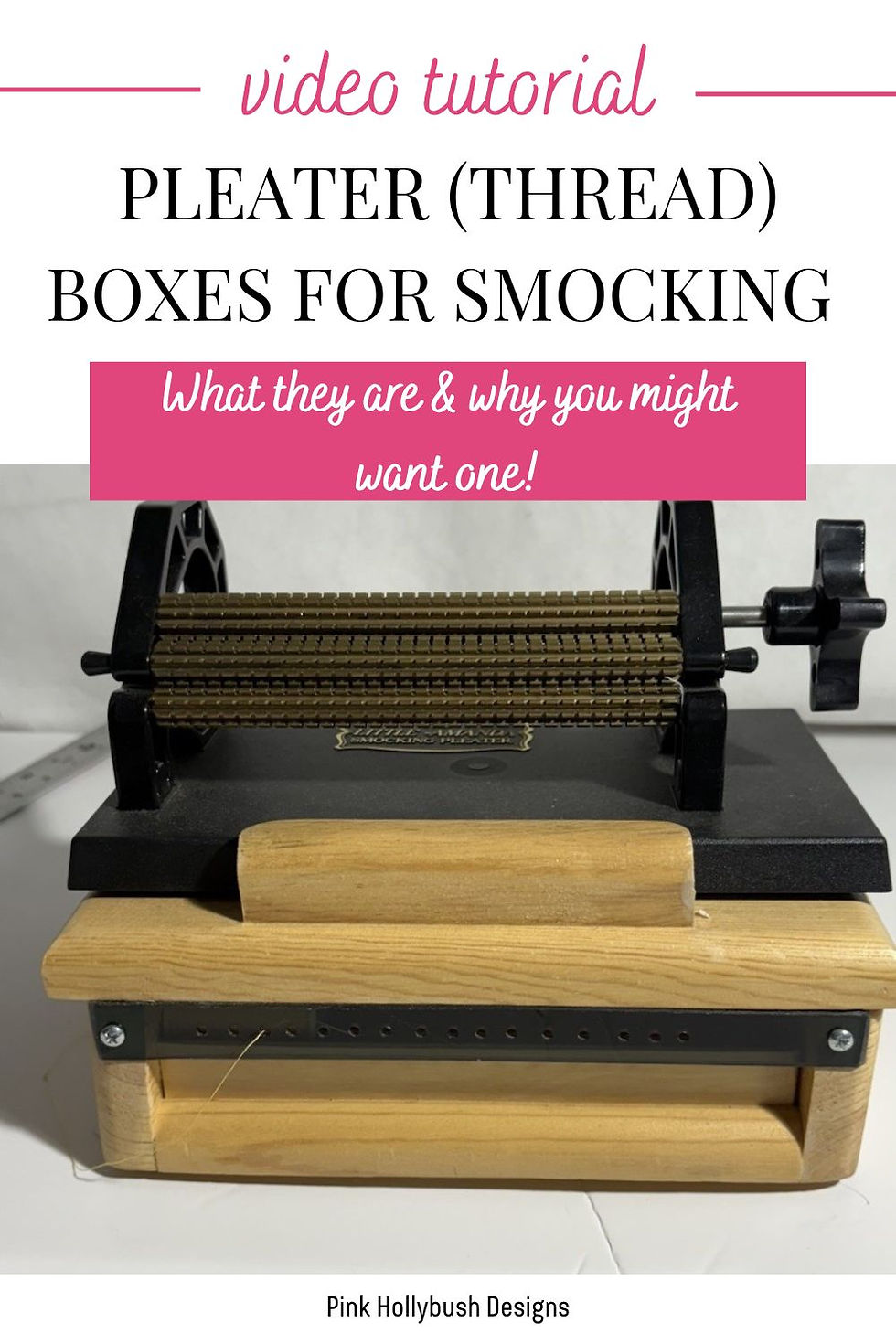

Update: I asked Judith Adams, a wonderful smocking teacher from Australia, if she knew what to do and she told me that Amanda Jane needles work beautifully in the Sally Stanley pleater. I promptly purchased some Amanda Jane needles and have been successfully using them in my Sally Stanley pleater for several years. If you need pleater needles, Pink Hollybush carries both the Amanda Jane and Read needles.